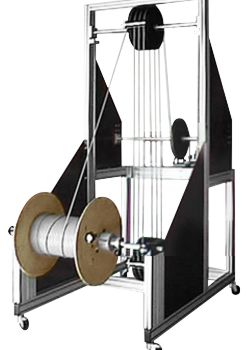

PF 250 Prefeeder

Strong feeding device for pulling heavy cables and similar materials directly from the drum and feeding them to further processing machines.

Discover the powerful feeding device for maximum productivity!

Our innovative feeding device sets new standards in production automation. With a belt feed driven on both sides and a heavy-duty transport belt with 6 bearings, it ensures reliable material feeding. The integrated pneumatic lifting device enables precise handling of heavy workpieces.

Increase your efficiency with flexible control options: You can control our feeder via an external analog signal or use the built-in dancer control. The latter has an intelligent safety shutdown in the event of a cable jam, which ensures smooth operation.

The basic speed can be easily adjusted using the potentiometer. In addition, programmable acceleration and braking ramps enable tailor-made adjustments to your requirements. Define the maximum speed according to your needs – completely individually and flexibly.

Thanks to the start-stop function via an external machine signal, you can seamlessly optimize your processes. The short-circuit-proof motor control ensures reliable performance and longevity. Our feeding device is perfectly designed to work harmoniously with other machines – thanks to the release signal that ensures a smooth flow of information.

Increase your productivity and precision with our state-of-the-art feeding device. Experience the future of manufacturing automation!

The machine is conform with the present and current CE-guide lines.

Subject to technical alterations.

• Regulation via an external analogue signal and/or the installed mobile arm

• Regulation of the mobile arm with security stop in case of cable jamming

• Basic speed adjustable via potentiometer

• Acceleration and brake ramp freely programmable

• Maximum speed freely programmable

• Start-Stop operation via external machine signal possible

• Short-circuit-proof motor regulation

• Free signal from and to other machines

Length of belt feed: approx. 400 mm

Feeder opening width: max. 50 mm

Feeder opening height: max. 50 mm

Speed: 0 – 3 m/sec

Pulling force: 600 N – 2000 N

Control: Frequency inverter

Drive: DC motor, frequency regulated

Power supply: 220/230 V

Width: 700 mm

Height: 400 mm

Depth: 500 mm

Weight: approx. 70 kg

• If this application is connected to a TEKUWA machine, its speed can be regulated by the

master machine