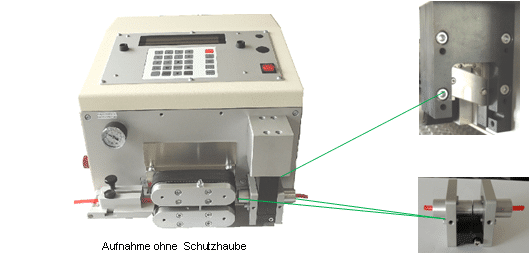

Cutting machine SC-30WR

Fast and precise electro-pneumatic cutting machine for cutting cables,

plastic and insulating tubes, flat cables as well as other thin

problematic materials

The machine is conform with the present and current CE-guide lines.

Subject to technical alterations.

Passage height: Ø max. 18mm

Advantage: Angle-precise and clean cut

Control and program comfort

– 16 bit microcontroller with 128 MB memory capacity,

AC servo technology

– Quick and easy operation via one

Dirt-resistant membrane keyboard with 4-line LCD display

Optionally, ring information can be used to control via a CAN bus system

other machines connected in a production line.

– The following values can be programmed item-specifically:

Number of pieces, subset, length, length correction, cutting time and subset waiting time,

Acceleration and braking of the feed, max. speed 0 – approx. 3m/s /

depending on the version (depending on the material).

– The software has article and order processing, e.g. wire harness production, with up to

up to 100 individual items per order.

The built-in Compact Flash card (128MB standard) allows you to save

up to 30,000 production programs.

– The machine has a cable limit switch.

Belt feed

Triple-bearing, material-friendly belt drive, with pneumatic opening and adjustable contact pressure via pressure regulator with display.

Soft conveyor belt for feeding the shrink tube according to the specifications

Special version cutting unit

pneumatically operated,

Pneumatic cutting unit with interchangeable insert for a hose diameter according to customer requirements, knife holder made of high-strength HSS steel to hold the 0.3mm thick cutting blade

Technical data

– Max. feed speed: 0 – 1 m/s

– Diameter (reduced): Ø 5mm max.

– Length: 1 – 999 999mm

– Length tolerance: +/- 0.15 at 12.25mm length

(positioning accuracy of the machine)

– Storage capacity: up to 30,000 programs

– Noise emission: less than 75 dBa

– Operating voltage: 220/230V AC

– Power consumption approx. 400 watts

– Operating pressure: 6 – 10 bar

Dimensions:

Length/depth/height: 375mm / 420mm / approx. 350mm

Weight: approx. 30 kg